Products

Outlook Stuctures – Building Enveloped Solutions

High technology architectural

structures and their enclosures.

Outlook Structures combines client support, engineering expertise, attractive systems components and project management processes to create unique architectural structures and their enclosures.

1. Steel Structures

Structural steel is a carbon based metal, available in many grades, that is used all over the world in the construction industry.

Steel Structures easily rusts, especially in an atmosphere with high humidity and corrosion. Typically, de-rusting, galvanising, painting, and routine maintenance are required for steel structures. Steel structural components are quickly produced in factories and put together on site. High production efficiency, quick site assembly and minimal building time are all benefits of factory mechanised manufacturing of steel structural components. Steel structures have advantages over typical reinforced concrete structures, including superior inhomogeneity, high strength, quick construction, good seismic resilience, and a high recycling rate. The design of a steel structure can be done in one of three ways: simple, continuous, or semi-continuous. Simple designs idealise their joints as flawless pins.

To design a steel structure, we need to determine whether the steel structure is suitable for the building, structure selection and layout, structural analysis, engineering judgment, component design and drawing preparation. Reasons why steel structure is the best choice, strength, cost saving, creativity, durability, low maintenance, quick constructions and sustainability. Advantages of steel structures are lighter weight, higher reliability, easy to make as a sealed structure, the steel structure can be assembled accurately and quickly, good vibration and impact resistance. Steel structures are highly suitable for residential buildings, towers, bridges, terminals, etc. It also benefits the house owners as it has fire and earthquake resistance. Additionally, it’s cost-effective and recommended for the construction of heavy industrial buildings.

2. PVC Tensile Structures

Unlike reinforced concrete structures, PVC (Poly Vinyl Chloride) is a building material and these PVC have a wide range of applications.

The approximate design life of PVC coated polyester fabric is 15-30 years, depending on the grade of PVC selected, location, and exposure to environmental pollution. PVC fabric warranties can range anywhere from 5 to 15 years, depending on the supplier and application. PVC fabric reflects around 89% of solar energy, allowing 9% visible transmission through the fabric. The rate of transmission is dependent on the colour of the fabric, coatings, printings and environment. These coatings can contain anti-fungicides. Therefore, the stronger the self-cleaning properties of the fabric, the less light transmission is interrupted by dirt adherence and aging of the fabric. With the ability to print on the fabric with ease, PVC is often used in projects where branding is important.

PVC is a strong fabric that can be folded, making it ideal for retractable and temporary structures such as tents, warehouses, remediation, and mining structures, which need to be demounted and stored often. PVC coated polyester is low maintenance, although it requires more frequent maintenance than self-cleaning PTFE and ETFE. Frequency of cleaning is dependent on the location of the structure, exposure to environmental pollutants, and the coating on the fabric. PVC is classed as a recyclable fabric, and is therefore an increasingly popular choice for green building as an alternative to rigid roofing. Although there are many processes of recycling PVC, the most common practice involves melting down the fabric to be reproduced. The process does not affect the lifetime of the recycled PVC.

3. PTFE Tensile Structures

PTFE (Poly Tetra Fluoro Ethylene) is selected for its low maintenance and translucency which utilises natural light

PTFE is highly reflective, making it ideal for shade structures, as it can withstand high temperatures (-73°C – 232°C) without transferring much heat. Testing has indicated that up to 80% of solar energy is reflected, with an 8% rate of absorption by the fabric itself. Some grades of PTFE however, can absorb up to 14% of solar energy, allowing a 12% rate of transmission through the fabric. PTFE can be spot-welded, or sewn which creates excellent fabric strength, and removes the concern of creases and splitting as a result of repeated folding and flexing of the material by improving durability. PTFE fabric has the ability to evenly disperse light, restricting the need for artificial lighting during the daytime, and creating an environment in which indoor plants and flora can survive.

Given the air permeability and flexibility of PTFE, it has tremendous sound absorption properties. External noise is capable of being isolated to meet the noise criterion of various buildings, while reverberation is directly relative to the internal size of the structure. Acoustics are clearly enhanced for smaller rooms, and can be treated to accommodate larger scale environments such as stadiums and aquatic centres. PTFE fabric is a low maintenance option that still offers exceptional quality, strength and a long lifespan. UV light bleaches the fabric, generating a bright and clean aesthetic. This is the defining feature of PTFE that differentiates it from conventional glazing. The self-cleaning properties created by the Teflon coating allow the fabric to resist moisture and remain clean and bright after installation.

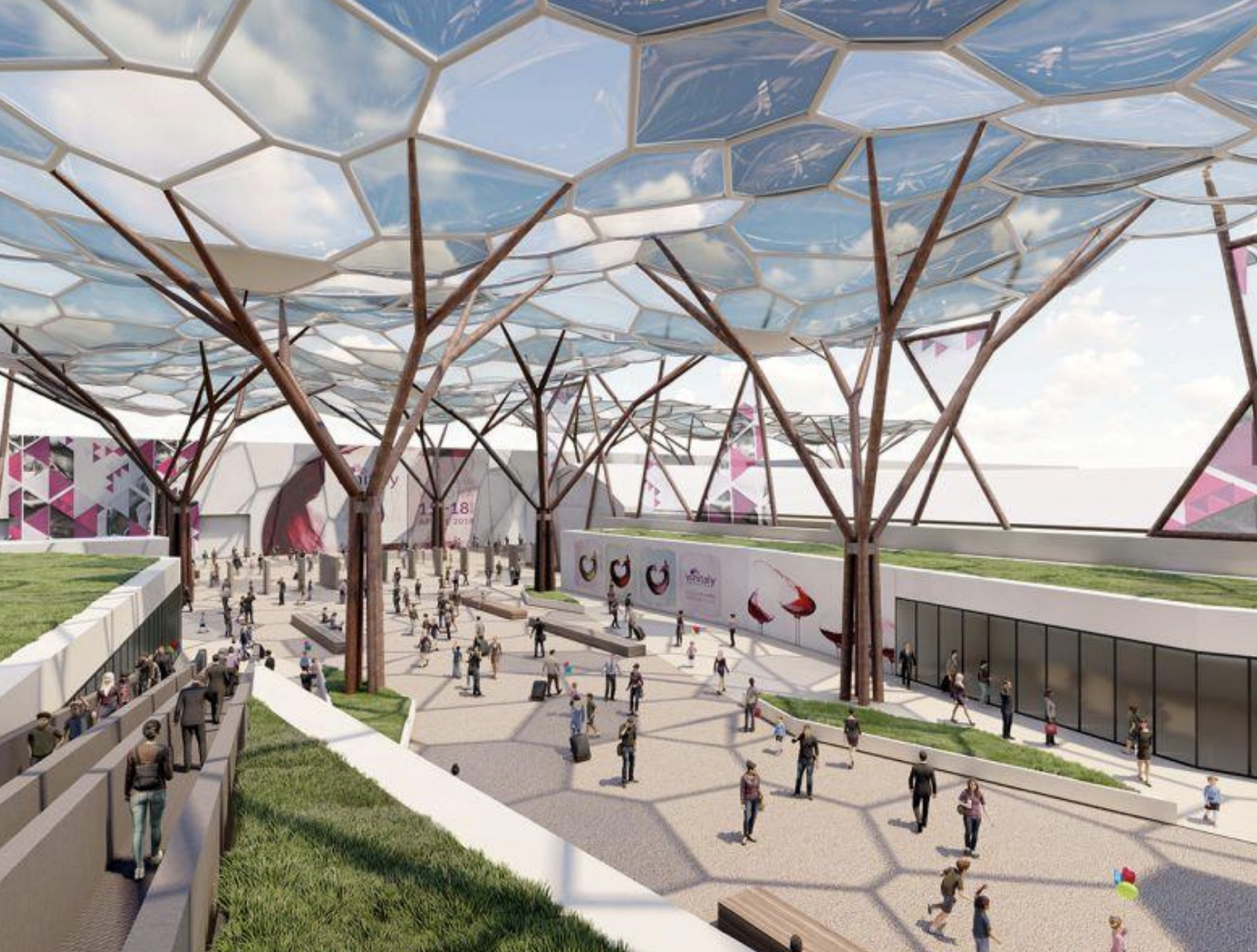

4. ETFE Systems

ETFE (Ethylene Tetra Fluoro Ethylene) is a fluoro polymer material. It is generally applied in the form

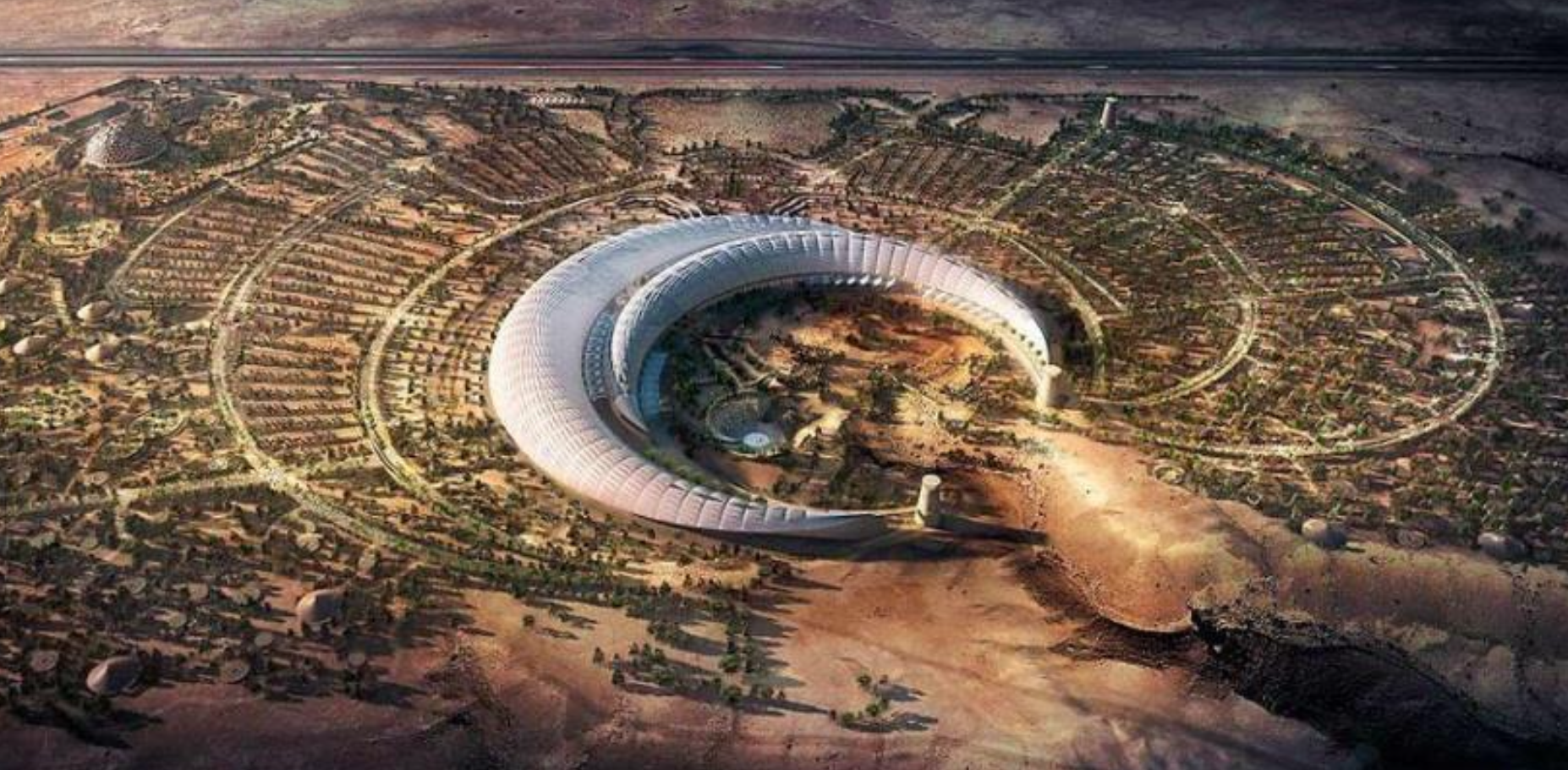

ETFE foil roofs are a popular choice for sporting stadiums as ETFE is a low weight, highly transparent membrane capable of transmitting up to 92% light. ETFE’s long life (40+ years), coupled with recyclability and low carbon footprint, makes it the material of choice for projects requiring Green Star and LEED certification. It is the most preferred material among Roofing Products due to its visuality and functionality. ETFE systems can be used for ETFE roofing, ETFE skylights and ETFE facades for stadiums, shopping centres, leisure and recreation centres, health-care facilities, schools and universities, walkways, and distinctive public shade structures.

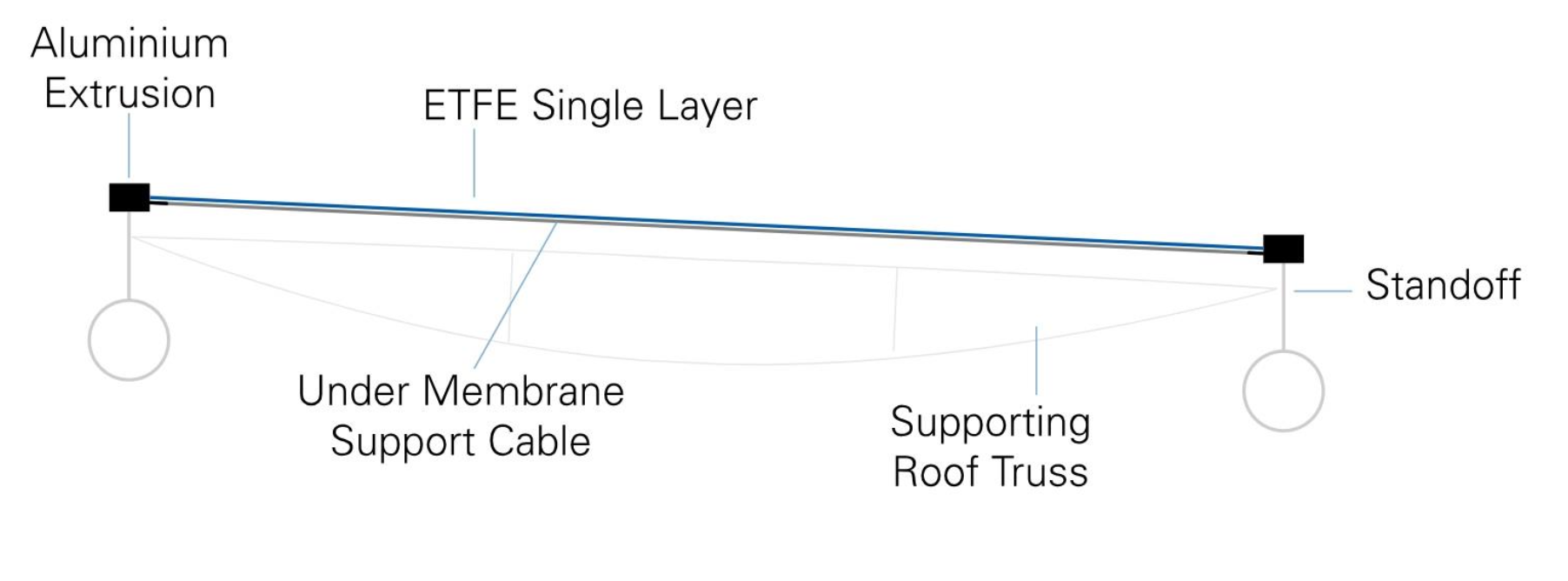

1. SINGLE LAYERED APPLICATION : ETFE System can be applied in a single layer to form a durable, lightweight glazed roof. Reinforced with cables, lightweight steel or aluminium to maintain shape and stability, a single-layer ETFE structure is perfect for allowing natural light into a building via applications such as skylights and atrium roofing. Flexible and able to form architecturally unique shapes, ETFE foil is also popular as an architectural building façade.

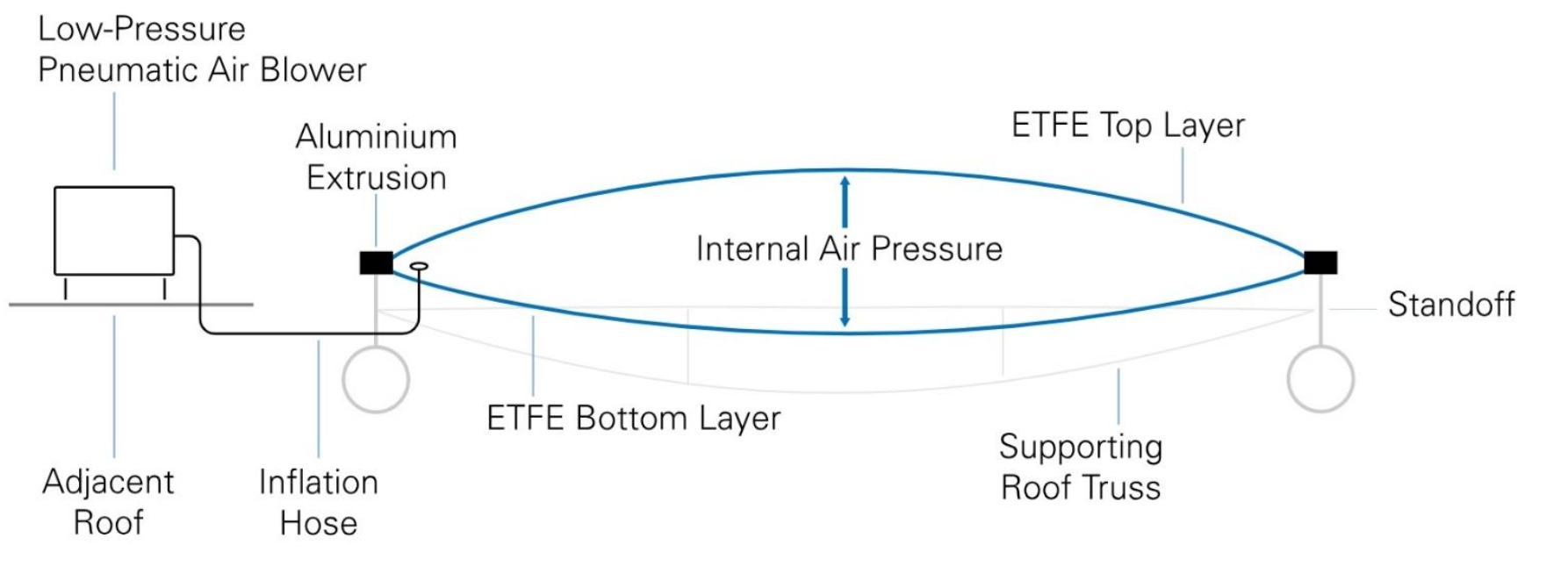

2. DOUBLE OR TRIPLE LAYERED APPLICATION : ETFE system makes use of air-filled foil pillows to create lightweight, thermally insulated and highly translucent roofing. The ETFE pillows, or cushions, are created with a pneumatic system which maintains low-pressure air between 2 or 3 layers of film. The cushions are restrained in aluminium extrusions and supported by a lightweight truss frame and cable system. Under typical loading conditions, cushions can range from 1 to 5 metres wide and reach up to 60m in length.

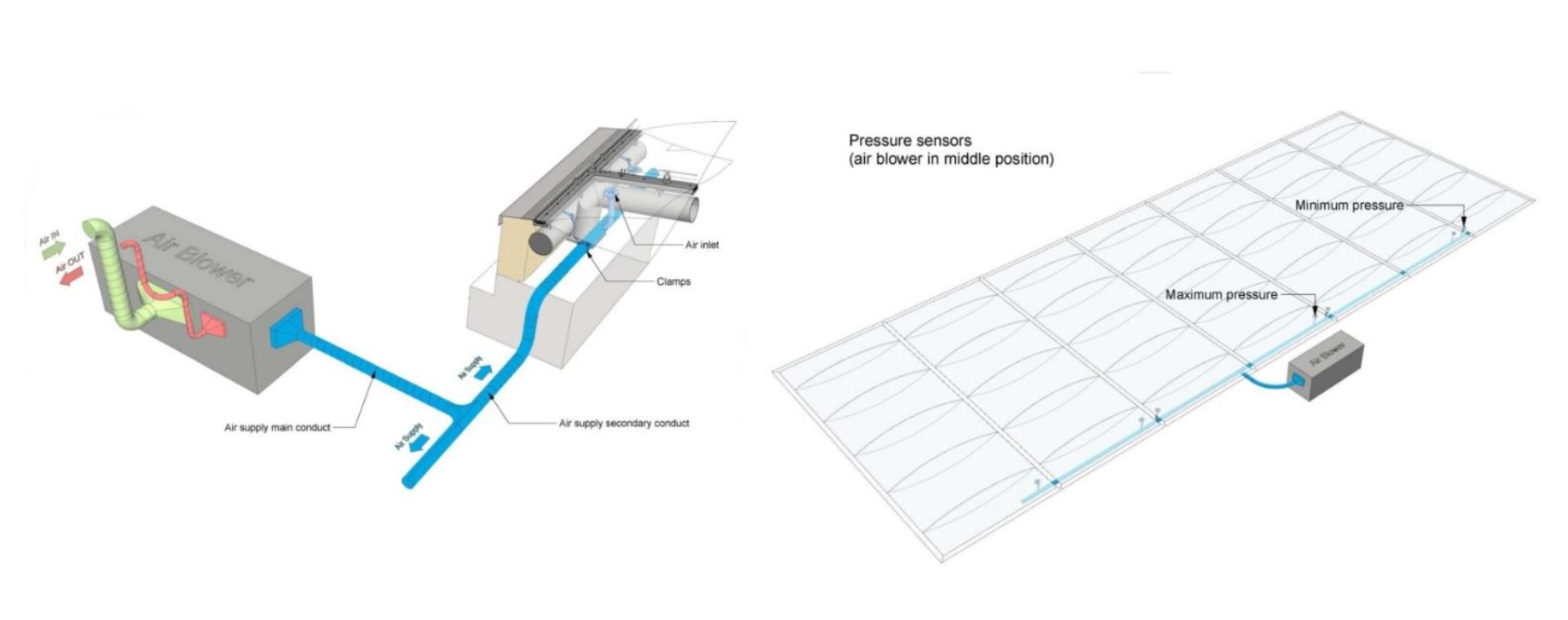

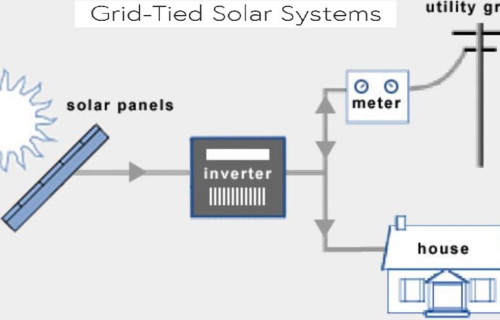

3. PNEUMATIC CUSHION SYSTEM : A multi-layer ETFE system is generally supplied with one or more inflation units. Each unit consists of two redundant blowers forming a backup system for guaranteed structural stability. The air when entering the machine will be dried to avoid condensation within the cushions. A series of pressure sensors continuously monitor the internal pressure of the cushions, maintaining them between 5 psi and 6 psi. In case of high wind or snow loads, sensors can automatically and continuously adapt the pressure to compensate for external loading. Depending on air temperature and humidity, one unit can supply a roof of up to 1400sqm. These units are UL certified and run on 110V power with consumption less than 1KW/h.

5. Acrylic Sheet

There are two popular kinds of Acrylic Sheets; cast and extruded. Cast acrylic sheets can be created

Extruded acrylic sheets use extrusion-grade polymer pellets as base. These pellets are created when a monomer is suspended in a water solution and a catalyst is added, creating droplets of polymers. These pellets are then fed into a machine called an extruder, which heats pellets until they have a molten, liquid consistency. From there, the molten plastic is put into a metal dye, which is like a mold. The dye then flattens on the molten plastic, creating a uniform sheet through pressure. Sheets can be made in a range of thicknesses depending on how much space is between the dye, the sheets are then fed into cooling rows, which makes the acrylic sheet solid. It holds a superior strength and impacts resistance ability compared to other alternatives. Acrylic Sheets are almost 15-20 times stronger than glass material.

Acrylic is generally used for a variety of applications that typically take advantage of its natural transparency and the impact resistance of certain variants. Common uses include lenses, acrylic nails, paint, security barriers, medical devices, LCD screens, and furniture. It is also often used for tanks, Industrial window glazing, safety shields, inspection windows, machine covers, and enclosures around exhibits. In merchandising, acrylic sheet has become the major sign material for internally lighted faces and letters, particularly for outdoor use where resistance to sunlight and weathering is important. Although acrylic offers heat resistance to a great extent and is harmless when burned, it is advised to avoid using it where flames can occur regularly.

6. Translucent Panels

Translucent panels have the ability to diffuse large amounts of usable light with a relatively low level of light transmission.

Insulated translucent wall panels are an attractive alternative to the traditional large glass windows that were often seen in the past. While those windows did admit light into an area, they were unable to block the accompanying glare that was an inevitable side effect of the natural light. Insulated translucent wall panels are designed to bring in the light and block the glare, as well as provide superior energy efficiency to the building. The translucent panels are designed to diffuse the amount of light that enters an area, creating a soothing glow that lends itself to the atmosphere that’s preferable for reading, writing, or quiet conversation. Because of the reduced glare, employees working at their desks can benefit from the natural light without suffering from irritating glare.

The translucent facades have UV blockers to remove any harm that the sun could cause as well as lower the heat index. Doing without the glare and the risk of sunburn is a bonus of insulated wall panels that glass fails to provide. The pure effects of the daylight without the glare-free the window from the need for shades or curtains, which would reduce the benefits of the natural light that makes such a difference in the look and feel of a room or a work area. The soft light that comes with translucent wall panels makes a significant difference in the interior appearance of your home. It’s 30 times stronger than acrylic and 250 times stronger than glass. Did you know that some police shields are made out of polycarbonate? If polycarbonate can stop a bullet, then translucent building materials made of polycarbonate can stop the rain.

7. Polycarbonate Sheet

Polycarbonate sheets have gained popularity for their incredible contribution to the environment.

Polycarbonate sheets are widely used in the commercial industry for their easy installation at the site. They don’t require complex machines or cranes in the process and can be fixed with the help of screws and support rods. These sheets are welded easily without much effort and cut with sharp-edged scissors and circular saws. The transparent polycarbonate sheets are protected against UV rays and are highly resistant to their impact. They are invariable up to 120 degrees celsius and hence maintain an exceptional surface and transparency. It is an ideal choice when you want maximum sunlight to come in without being harmed by its rays. The greenhouses are an example of polycarbonate roofing. It helps the plants to grow well with a sufficient amount of light and energy.

Polycarbonate sheets are resistant to fire, these sheets prevent the flow of excess heat, hot gasses, and flames. It also does not expand during the heat and does not impose additional stress on the buildings. Polycarbonate sheets require low maintenance, unlike glass roofing sheets. These types of sheets are commonly used at garages, skylights, greenhouses, and pergolas. It protects the internal structure from wind, moisture, and external temperatures. It provides warmth during the winter and a cool atmosphere during the summer. It is used in construction buildings, interior designs, and agricultural buildings. Types of Polycarbonate sheets are clear, coloured/Tinted, mirrored, bullet proof, abrasion resistant (AR), Anti-Static, Flame retardant, FDA Approved, Multiwall.

8. Glass Glazing

Glass roofs are one of the most effective ways of getting natural light into a space. Glass roof is composed

The safety glass is perfect for installation in Indian homes as the weather is extreme when at its peak. An extreme heat wave is experienced during the summer season while the spine-chilling cold waves disturb the lifestyle during the winter season. This glass acts as a protector from external intrusion and keeps the temperature-controlled without making the family members feel the need for Air-Conditioners or room heaters. These characteristics of glass roof make it an energy-efficient product, as it lowers electricity consumption which reflects in the power bill. One of the biggest advantages of glass roofing is the minimized noise pollution that most of us deal with every day. A home with this type of roof has an increased value because multiple benefits are availed by making one-time investments.

High maintenance cost is the biggest disadvantage as the material is fragile in comparison to the brick, wood, steel and other. Thus, even a small crack in the roof lets you change the entire frame and thus it is expensive. Another disadvantage of the glass roof is leakage. This problem can arise in case the glass is not fitted accurately. This problem results in the incorporation of dust and water inside the abode during the bad weather. A glass roof offers multiple benefits. It connects the internal space with the outside environment and provides the best of both worlds. However, it is essential to undertake thorough research and select the right glass type for maximum benefits. Different types of glasses are Laminated Glass, Tempered Glass, Thermal Glass and Security Glass.

9. Windows and Door

Window is defined as an opening in a wall of a building to serve one or more of the functions like natural light,

Casement Windows: These are hinged windows that open outward, allowing maximum ventilation. They are easy to operate and provide an unobstructed view. Double Hung Windows: These windows consist of two sashes that slide vertically, enabling both the upper and lower parts to open. They are great for controlling airflow and are common in traditional homes. Awning Windows: Awning windows are hinged at the top and open outward. They can be left open even during rain and prevent water from entering. Sliding Windows: Sliding windows have horizontally sliding panels. They are space-saving and easy to operate, making them suitable for modern homes. Picture Windows: These are large fixed windows designed to provide an unobstructed view of the surroundings. They are a choice for showcasing scenic views.

Entry Doors: Entry doors are the main doors that provide access to a building. They come in various materials, such as wood, fiberglass, and steel, providing different levels of security and insulation. French Doors: French doors consist of two panels that open outward or inward. They add elegance and charm to any space and are commonly used for exterior access. Sliding Doors: Sliding doors have one fixed panel and one sliding panel. They are space-saving and allow natural light to enter. Patio Doors: Patio doors are designed to connect indoor and outdoor living spaces. They are made of glass, providing unobstructed views and a seamless transition. Bifold Doors: Bifold doors consist of multiple panels that fold and stack against each other when opened. They are a choice for maximizing openings and providing a wide access point.

10. Metal Sheet Roofing

A metal roof is a building component that requires proper design, specification and detailing.

Different materials have different levels of strength and durability. Weather elements in a given area can also impact durability. Some places get plenty of sunshine, while others get much rain. You want a metal roof sheet that offers adequate protection. During the winter, snow may accumulate above the roof. This means you need a thicker roof sheet that can withstand the load; otherwise, it will fall into your building. Metal roofs can easily last anywhere from 40 to 70 years, depending on the quality and type of metal, while traditional asphalt roofing materials have a life expectancy of 12 to 20 years. When properly installed, the metal roofs can withstand wind gusts of up to 140 miles per hour, will not rust over time, and may be impact-resistant.

Metal roofs do not necessitate the costly maintenance that other roofing materials frequently necessitate. However, they should regularly be inspected to ensure no repairs are required. Metal roofs will not spark and ignite into flames during an emergency, like a wildfire or lightning strike. Metal roofs tend to reflect the sun’s UV and infrared light rays, which contribute to radiant heat on the roof surface, which makes the place 25% cooler than any other roofing. Metal roofs not only have a recycled content of 25-95 %, depending on the material used, but they are also 100% recyclable at the end of their life as a roof. A properly installed metal roofing sheet is bound to last as long as the house itself. These roofs have unique durability that can withstand elements such as wind, gusts and dirt and still not crack.

11. Expanded Metal Mesh

Expanded metal mesh is a plate or sheet cut from metal sheets and stretched into a mesh.

When choosing expanded metal for your fence application, you will need to determine which style or diamond size is best for your application. Expanded metals can also be used on facades and walls, where they can be integrated into the ceiling. Expanded metal can be easily used in ladder structures, cable plants, cabinet doors and ceiling coverings. Expanded metal product types that adapt to Modern structures and give life to designs that are far from aesthetic concern are determined as standard in accordance with the area to be evaluated. Because it is prepared in one piece without welding, it is of great importance that the measurements are handled correctly. In this way, expanded metal designs are placed in spaces to fully comply with the requirements of the structure.

Expanded metal mesh is lighter than conventional metal sheets. Expanded metal mesh sustains weight as well as stands up to stress much better than woven metals or joint welds. Expanded metal mesh can boost acoustics and also offer sound insulation. Expanded metal mesh permits air and light to relocate easily. Expanded stainless steel mesh is frequently used to make fences, walkways, shelving, display units, security guards, sound attenuation and grates, as the material is very durable and strong. Expanded stainless steel mesh offers many advantages and features, making it a worthy material for a variety of applications. Some of the benefits of expanded metal mesh include its cost-effectiveness, durability, and versatility. Additionally, expanded metal mesh sheets are easy to install and easily cut to fit specific sizing requirements.

12. Metal Composite Panels

Metal Composite Panels were introduced more than 50 years ago as aluminum composite material (ACM).

Metal Composite Panel has a number of advantages compared to single-layer metal sheeting, including: weather resistance, acoustic insulation, thermal insulation, better durability, they do not wrinkle as the external skins are bonded to the core under tension, they are lightweight, metal composite panels have become very affordable compared to other systems. They can be more cost-effective and can be installed faster than precast panels, granite or brick exteriors, and have reduced structural support requirements because of their lighter weight. Manufacturer quality control ensures the sheet is produced flat and fabricator engineered systems retain that flatness through installation. MCP not only provides flatness consistency, but also consistency with coil coated finishes.

Initial construction costs are often lower with Metal Composite Material systems because panels can typically be installed faster than alternative exterior products such as precast, granite or brick. The lightweight MCP systems can save money by reducing structural steel requirements. In addition, ongoing maintenance costs are reduced as a result of continuing improvements in paint finishes. Today’s Metal Composite Material retains their luster for decades ensuring that the building maintains its aesthetic appeal and its property value for the long term. This longevity makes a difference when it comes time to sell the building. Facilities clad with high-tech MCP systems retain their curb appeal and never look dated, often reducing the need for refurbishing costs. MCP makes use of recycled materials like aluminium, minerals, and polymer.

13. ACP Cladding

ACP cladding, also known as Aluminium Composite Panel cladding, is a popular architectural materials used to

When it comes to selecting the right ACP sheet thickness for different application areas, the thickness of ACP sheets directly influences their suitability for specific projects, particularly in relation to wind load. Thicker ACP sheets, ranging from 3mm to 6mm, provide enhanced structural integrity and durability, making them an excellent choice for areas with higher wind loads, such as high-rise buildings or locations exposed to strong winds. On the other hand, thinner ACP sheets, typically 3mm, are lighter and more suitable for applications like signage, display boards, and interior design, where wind load considerations may be relatively lower. ACP Sheet Applications are for Exterior cladding, Interior cladding, Signage and Advertising, furniture and cabinets, transportation and Industrial applications.

ACP Sheets can be bent, fold, turn easily, no crack risk, flatness, available in a wide range of colours and finishes like wood, stone, mirror, sand, and 3D. Lightweight, UV ray resistant, fully recyclable, withstands extreme weather conditions, Easy to clean. ACP sheets are often used for façades, canopies, overhangs and soffits. ACP sheets are used in such as partitions, false ceilings, cupboards, table tops, wall panels, column covers, and more. ACP sheets are used for signage, kiosks, totems, POPs, fascia and advertising etc., due to their weather resistance and durability. ACP sheets can also be used for furniture such as modular kitchens and cabinet design, ACP sheets can be used for bus bodies, trains, Metro rails, and other vehicles. ACP sheets are also used in industrial applications such as machine covers, panelling, and enclosures.

14. Solar Roofing

Solar panels use photovoltaic cells to absorb the sunlight and convert it into electricity.

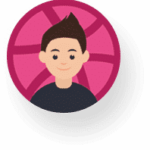

However, the generated electricity is in the form of DC current, which is incompatible with home appliances. A solar inverter converts the DC current into AC. After which, the electricity can be safely used for various purposes. Concurrently, a solar meter tracks the solar rooftop power production and identifies potential issues. In essence, this process demonstrates how solar energy is transformed into usable electricity. There are three types of solar system installations—grid-tied, off-grid, and hybrid. Grid-tied installation is the most common type wherein the panels are connected to the public power grid. The main benefit of doing this type of installation is that you can get net metering which will refund your energy bill with any excess solar-generated electricity.

An off-grid installation is stand-alone that does not connect to the public power grid. This means that you’ll need to store energy from your solar panels in batteries and use it when needed. Hybrid is a combination of a grid-tied with the battery storage capacity of an off-grid system. Solar energy can be used for heating water, powering homes and buildings as well as charging electric vehicles. Unlike other renewable energy sources, solar power does not require water. Thus, it helps in water conservation efforts and is a more sustainable option for electricity generation. Solar rooftop systems can be the perfect way to help reduce your energy bills and increase your energy independence as a homeowner or a business owner. Making the investment toward a more sustainable and cost-effective future is at your fingertips with rooftop solar energy systems.

Our customers feedback!

We are proactive in finding solutions for our clients that best achieve their goals. We understand that lasting relationships are the lifeblood of our business so we pay personal attention to our clients by focusing on them as individuals.

Chirly Winston

Outstanding service! Outlook Structures delivered top-notch service, exceeding expectations. Their professionalism, attention to detail, and commitment to quality set them apart. Highly recommend for exceptional results.